INTAKE

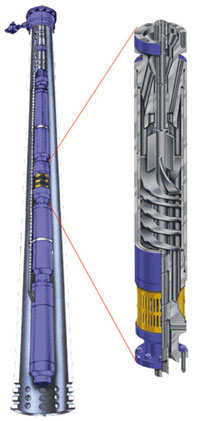

The intake can be as simple as an opening to allow fluid into the pump or can be one of the most technically advanced items on an ESP when dealing with large quantities of free gas.

The construction of a standard intake only needs to consider bearing selection, shaft material and housing material. If free gas is present the design of the intake can radically change.

The construction of a standard intake only needs to consider bearing selection, shaft material and housing material. If free gas is present the design of the intake can radically change.

Radial impellers can handle up to 10% free gas and mixed flow impellers can handle up to 20% free gas without a special intake. However, once those levels are exceeded the possibility of gas locking exists. When gas locking occurs the production from the ESP will drop to zero instantly and the ESP will shut down. This is a situation where correct design could improve production.

If production up the annulus is possible static and rotary gas separators can be considered. If flow up the annulus is not possible gas handling devices that blend the fluid to prevent gas locking can be considered. With various combinations of devices up to 70% free gas downhole can be produced with an ESP.