CLAMPS

The electric cable used for ESPs is unable to support its own weight. As a result attaching the cable to the tubing not only keeps the cable relatively straight, it supports the weight of the cable. One of the worst situations that can occur with an ESP is if a larger section of cable is unsupported and falls in the well. There have been cases where the well has been abandoned because ESP cable is very difficult to fish.

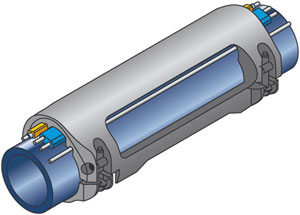

The most common method of supporting cable is a galvanized, stainless steel or monel band that is strapped around the tubing and cable usually by means of a pneumatic banding gun and secures the cable by friction and cable deformation. However, for certain applications a more durable and less damaging method is desired so clamps are used. A clamp is cast or pressed metal device that involves bolts or pins to hold the camp together and is often located around a tubing collar to avoid the need for friction or deformation on the cable.

The most common method of supporting cable is a galvanized, stainless steel or monel band that is strapped around the tubing and cable usually by means of a pneumatic banding gun and secures the cable by friction and cable deformation. However, for certain applications a more durable and less damaging method is desired so clamps are used. A clamp is cast or pressed metal device that involves bolts or pins to hold the camp together and is often located around a tubing collar to avoid the need for friction or deformation on the cable.

At times clamps are used around the ESP equipment to hold the MLE in place. These are normally referred to as protectorlizers.

Both the clamps and protectorlizers can be manufactures to match the tubing and cable size and often are designed to accommodate other control lines and wires. Cable bands need to be replaced with each pull and run, while clamps are reusable.